FEM Analysis on Paradisco for Motorcycles

Share

At LP9Engineering, we believe in combining academic theory with practical applications, and this recent project is a perfect example of this philosophy. As engineering students, my colleagues Edoardo Scianca, Martino Rovesti, and I decided to put our academic knowledge into practice by conducting a study focused on improving the performance of a motorcycle we ride in our free time. This exercise was part of our exam preparation, but it was also driven by our shared passion for engineering and motorsports.

What is FEM and why should we use it?

The Finite Element Method (FEM) is a powerful numerical simulation technique that helps us understand how a component behaves when subjected to forces, vibrations, or other stresses. By discretizing a model into a network of small elements, the FEM allows us to solve mathematical equations that calculate:

-

Stress: The internal forces within the material.

-

Displacement: The changes in position of the component under load.

Using FEM, we can predict how a component will behave in the real world. This allows us to optimize its design and material selection before moving on to the manufacturing phase, saving time and resources.

Our study: Designing a brake disc guard for the KTM EXC

For this project, we chose to design and analyze a brake disc guard for a KTM EXC . Our goal was to simulate the worst-case load scenario: a force of 3000 N along the X-axis, representing a collision between the motorcycle and an obstacle at the most critical point of the guard. Since this was a preliminary analysis, it was not necessary to go into more complex details at this stage.

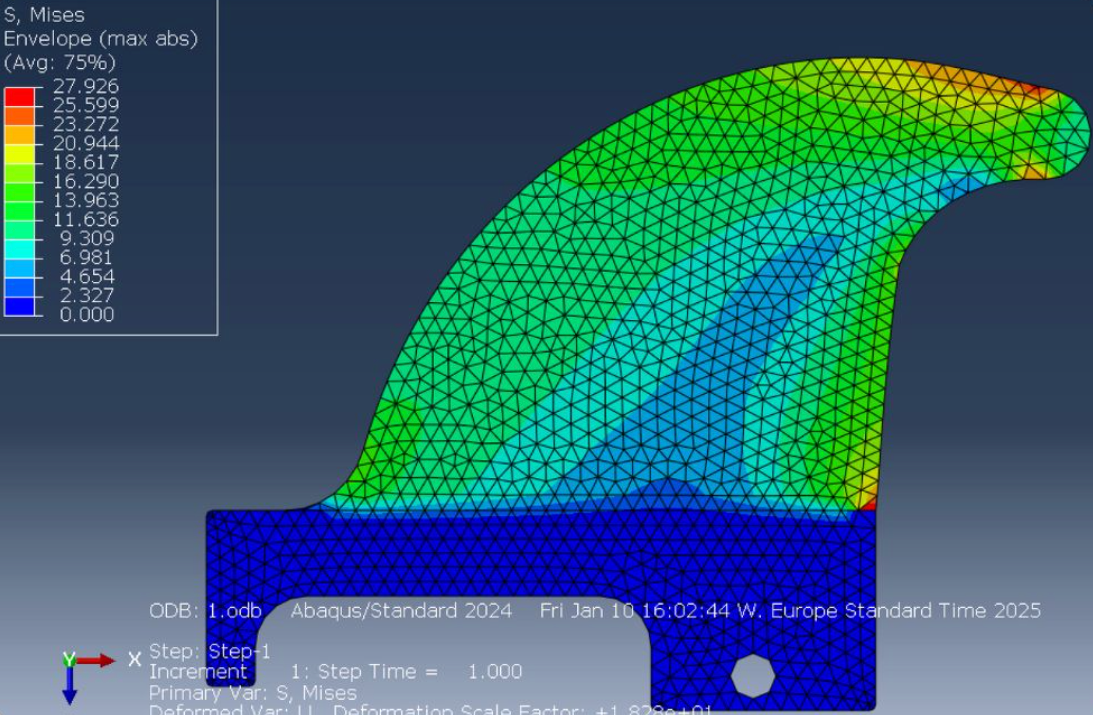

Simulation results

The simulation provided us with valuable information:

-

The component does not fail under the applied load.

-

The maximum recorded displacement was only 0.965 mm.

-

Despite being 3D printed with PLA+, a relatively weak material, the design proved capable of withstanding the applied load. Further simulations suggested that using more advanced materials, such as aluminum or high-performance polymers, would further improve its performance.

A combination of study and passion

This project was a fantastic opportunity to apply FEM to a real-world challenge. It allowed us to deepen our understanding of simulation techniques, working on something we're passionate about. By bridging theory and practice, we were able to make our academic experience more tangible and engaging. Engineering, in our opinion, thrives on experimentation and hands-on learning, and this project was an exciting step in preparing us for future professional challenges.

At LP9Engineering, we're committed to pushing the boundaries of engineering through innovation and hands-on experimentation. If you're interested in similar projects or have ideas for collaboration, please don't hesitate to contact us!

#FiniteElementMethod #Engineering #MechanicalEngineering #3DPrinting #Simulation #KTMEXC #AcademyAndPractice